All Our Expertise

At A Glance

Development & Engineering

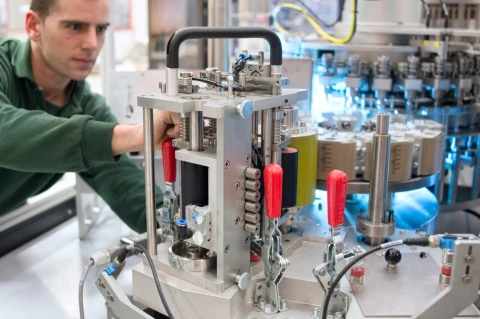

The mechanical engineers within our engineering department develop tooling for manufacturing complex parts and assemblies. Our system engineers translate the product requirements into system development specifications for functional and dedicated qualification tools. Our goal is to have all AAE products comply with the specifications our customers require.

Our Automation Platforms

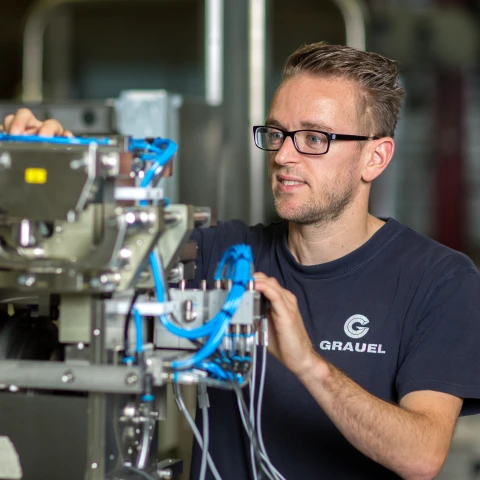

We provide turnkey, custom-made printing and assembly automations under the brandname Grauel. By offering various automation platforms, Continuous Motion (CMS), Indexing Motion System (IMS) and Flexible Motion System (FMS), we are able to provide our customers with tailor fit solutions.

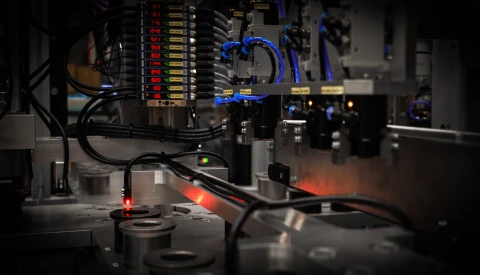

CMS Automation Platform

Our Grauel continuous motion machines have a modular design and are efficient and compact. The machine works with one central motor that drives the individual dials by a gear train mounted underneath the process plate. This way, all dials are mechanically synchronised.

That is how we are able to achieve a high output of up to 500+ parts per minute.

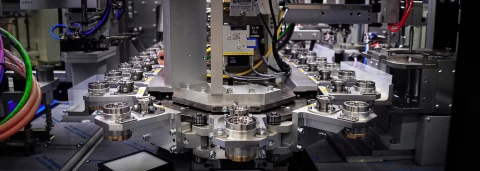

IMS Machine Platform

For assembly or printing & assembly machines, we use our linear conveying system (LCS). The LCS system is a highly robust, low maintenance chain with 125-mm milled links. The chain has a very accurate position tolerance and is spring loaded.

With a limited number of automation processes, we use round indexing tables.

FMS Machine platform

The Flexible Motion System does what it says: it guarantees maximum flexibility! The key in FMS is the fact that the product carriers are independently controlled, which enables processing of different cycle times within a single machine. We offer machine building blocks under our brandname Grauel that can easily be changed and tooled up with different printing and assembly processes. The platform controls are decentralised, enabling the operator to switch to different products quickly, easily and safely.

The FMS platform is ideal in low-volume high-mix situations.

Our Printing and Assembly Technologies

Our technology regards printing and assembly, but also printing and assembly combined in one machine. This results in compact automations, efficient in-line production and therefore very low manufacturing costs per product.

Printing Technologies

Based on our customers' preferences and requirements we find the right printing technique. We offer the following printing techniques:

- Dry-Offset / Flexo

- Inkjet

- Pad Print

- Laser Marking

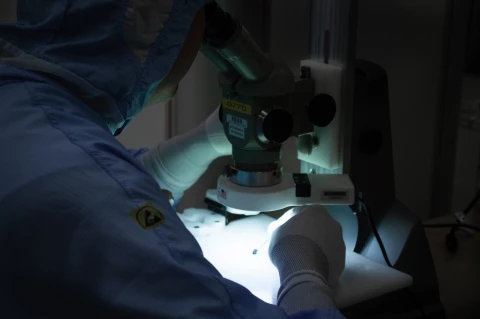

Our High Tech Cleanroom

Since we run a high tech ISO class 7 cleanroom for our assembly department, we know what it takes to make (printing and assembly) machines operable in our customers’ cleanroom environment.

Together we make it easy to access and ultra clean.

Pushing Technical Boundaries

Where our groundbreaking technology contributes to a smarter, healthier, more sustainable and simply more beautiful world.

Our hightech Cleanroom is equipped with:

- Local ISO class 5 mini-environments for extremely clean assembly and qualification;

- Ultra-High Purity zones with dedicated instruments;

- Logistics ring, including wet cleaning and drying processes;

- Wet-vacuum (up to 0.08 bar absolute);

- RGA equipment;

- Leak test equipment (vacuum and overpressure);

- Cleanliness qualifications: Particles: in gas XCDA and ultrapure water. Residual Gas Analysis. Blacklight inspection in a dedicated controlled room.

Cleanliness qualifications

Particles: in gas XCDA and ultra-pure water. Residual Gas Analysis. Blacklight inspection in a dedicated controlled room.

Pushing the boundaries of technology together with my colleagues and surprising the customer is the best thing there is!

Niels van Vroonhoven

Assembly

Designing, engineering and assembling machines is part of our DNA. With our highly skilled mechanics, mechanical, electrical, software and process engineers, we assemble a wide range of devices according to our customers’ specifications as well as unique, 100% custom-made ’specials’.

What I enjoy the most? Facing new challenges everyday!

Christian Seijkens

Project Management

Our interdisciplinar project teams manage various new product introductions, each project team consists of:

- A project Manager

- Manufacturing Engineers

- NPI Engineers

- NPL Engineers

Product Lifecycle

Management

After the validation of the product design, industrialisation of the manufacturing process is key to securing continuous delivery of our customers' products.

Supply Chain Management

We manage a global supply chain in collaboration with our procurement and logistics department.

Manufacturing Engineering

Our manufacturing engineers manage product and process quality. They assure secure manufacturing in a controlled environment.

GAMP Validation

Our project approach is V-model based, which is a perfect guaranteed start, should you require a GAMP validation trajectory. It is all about minimising patient risk and showing a well-automated manufacturing practice that covers all project stages: DQ, IQ, OQ and PQ.

Our Key Technologies

Our continuous investment in people, the most up-to-date technology and unmanned manufacturing guarantees that we are as productive, cost-efficient and innovative as possible.

We understand our customers’ DNA. Developing a manufacturing process with our engineers and manufacturing experts results in secured product delivery.

Our Key Technologies enable us to manufacture and assemble highly complex products by using the following techniques:

Machining

Our highly skilled milling and turning experts guarantee quality and craftsmanship by applying the highest level of speed and flexibility to prototyping, single items and serial production.

Micro-laser Processing

Our DMG Sauer Lasertec 80 centre ensures us of the latest (micro) laser cutting, welding and drilling technology. By using removable 5-axis machining, we are able to produce highly complex products.

3D-printing

To optimise our early customer involvement and provide the right advice, we have acquired a 3D metal printer. The main advantages are a shortened development cycle, creation of complex shapes, sustainable production and the ability to be involved with the customer as early as possible.

Sheet metal and construction

Our people play a crucial role within our sheet metal and construction department because the emphasis is on prototyping both individual and small product series. This requires expertise in welding and sheet metal.

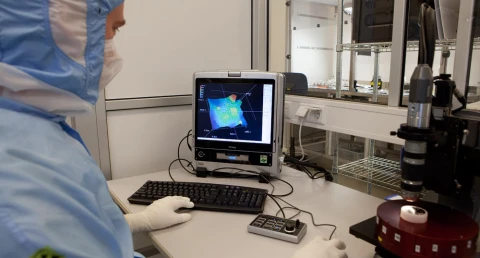

Measuring

Intermediate and final control takes place in our fully equipped and conditioned measuring department. Our measuring experts verify component dimensions by using touch and optical methods, all within the micron range.

Getting the space and opportunity to develop yourself while being surrounded by great colleagues: that's AAE.

Kurt Wils

Service

Our helpdesk is ready to assist you with all your questions about the machine, spare parts, service, upgrades or process. We can also provide a maintenance contract for the machine. If you interested in more information about the machine, please request training. We also offer consulting and sample printing. To keep the machine in perfect condition, we can monitor it and make recommendations for preventing downtime.