Consumer Goods

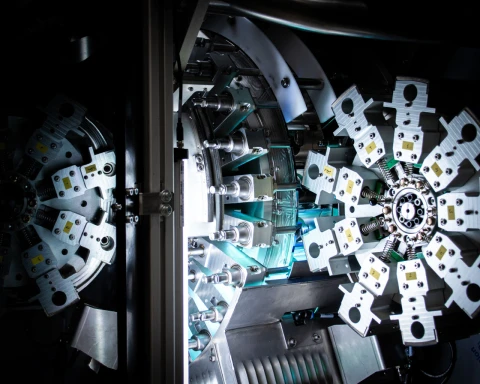

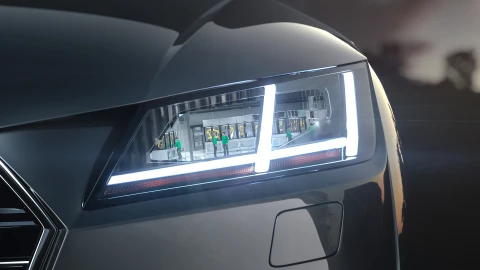

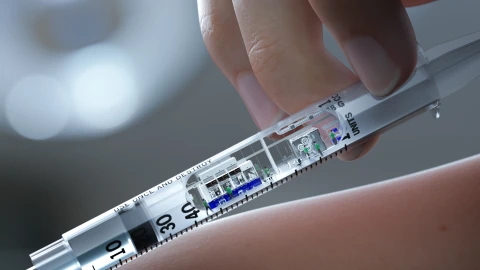

Engineering and assembly for the consumer goods market requires a specific skill-set and expertise. Speed, durability and impeccable output results. Exactly the things we love to put our expertise at work at. We offer tier-one design and contact manufacturing for OEM companies in our Advanced OEM systems business line and printing and assembly automation in our business line Printing and Assembly Automation.

Here we shed some light on the solutions we provided for Heineken, Newell and Ranpack. These are just some of the many possible solutions that we can provide for this specific market. We love a challenge so feel free to contact us with yours.