Proud to be part of

next level Dry Offset Printing

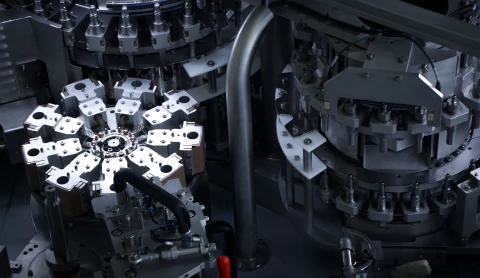

Continuous Motion Printing System

At Grauel, we have decades of experience integrating dry offset printing in high-speed systems that deliver benchmark-establishing quality in both printing and assembly. Our print systems are extremely versatile and take all sorts of materials, products and shapes in their stride. Our printing and assembly systems offer you complete freedom in fine-tuning the optimisation of your production process. Combining printing and assembly in a single machine reduces your plant footprint and drives down costs.

Pre-Treatment and Curing

A good beginning is half the battle, this is all too true for dry offset printing. The correct pre-treatment and curing of products make a world of difference in the field. We have a long track record of integrating Corona, Flame and Plasma pre-treatments to facilitate high-quality ink adherence. Our fully equipped laboratory supports finding the best pre-treatment and curing methods (including IR, UV mercury, UV-LED) for your needs. These solutions are then integrated seamlessly into your machine.

Ink Selection and Support

Hand in hand with pre-treatment and curing is careful attention for ink properties; one cannot exist confidently without the other. We can supply you with inks created especially for medical devices and food preparation applications. We even carry a full range of (LED) UV inks that can be cured at high speed. Our specialists select or prepare an ink that is up to the job. They will also be on hand if in the future you need support while running the machine or if you need to adapt to changing circumstances or legislation.

Validation

The projects build on your behalf are always V-model based, which guarantees a smooth transition into any necessary future GAMP (Good Automated Manufacturing Practice) validation. Minimising patient risk and demonstrating properly automated manufacturing practice that covers all the stages of a project: DQ, IQ, OQ and PQ.

Pushing Technical Boundaries

We push the boundaries of what is technically possible to empower you. With every high-end solution meeting your exact needs and requirements. To boost your competitive edge in your industry, so that you can lead the market through smarter, faster, more stable and cost-effective manufacturing.

Back to Printing & Assembly Automation